828 U A.I. BE.S.T. Steel

828 U A.I. BE.S.T. Steel is pure strength. Its scale is made of steel and gives the over-and-under unparalleled strength and excellent stability, reducing recoil. BE.S.T. (Benelli Surface Treatment) treatment covers steel receiver, Lock Plate, safety, opening handle, fore-end iron. A coating that goes beyond the usual, thanks to a resistance to corrosion and wear incomparable to all other treatments on the market. Equipped, moreover, with the innovative Benelli Advanced Impact barrel-choke system, this over-and-under ensures superior performance and extreme resistance, in any weather condition.

Technical sheet

GAUGE

12

CHAMBER

76 mm - 3"

BARRELS AND CHOKES

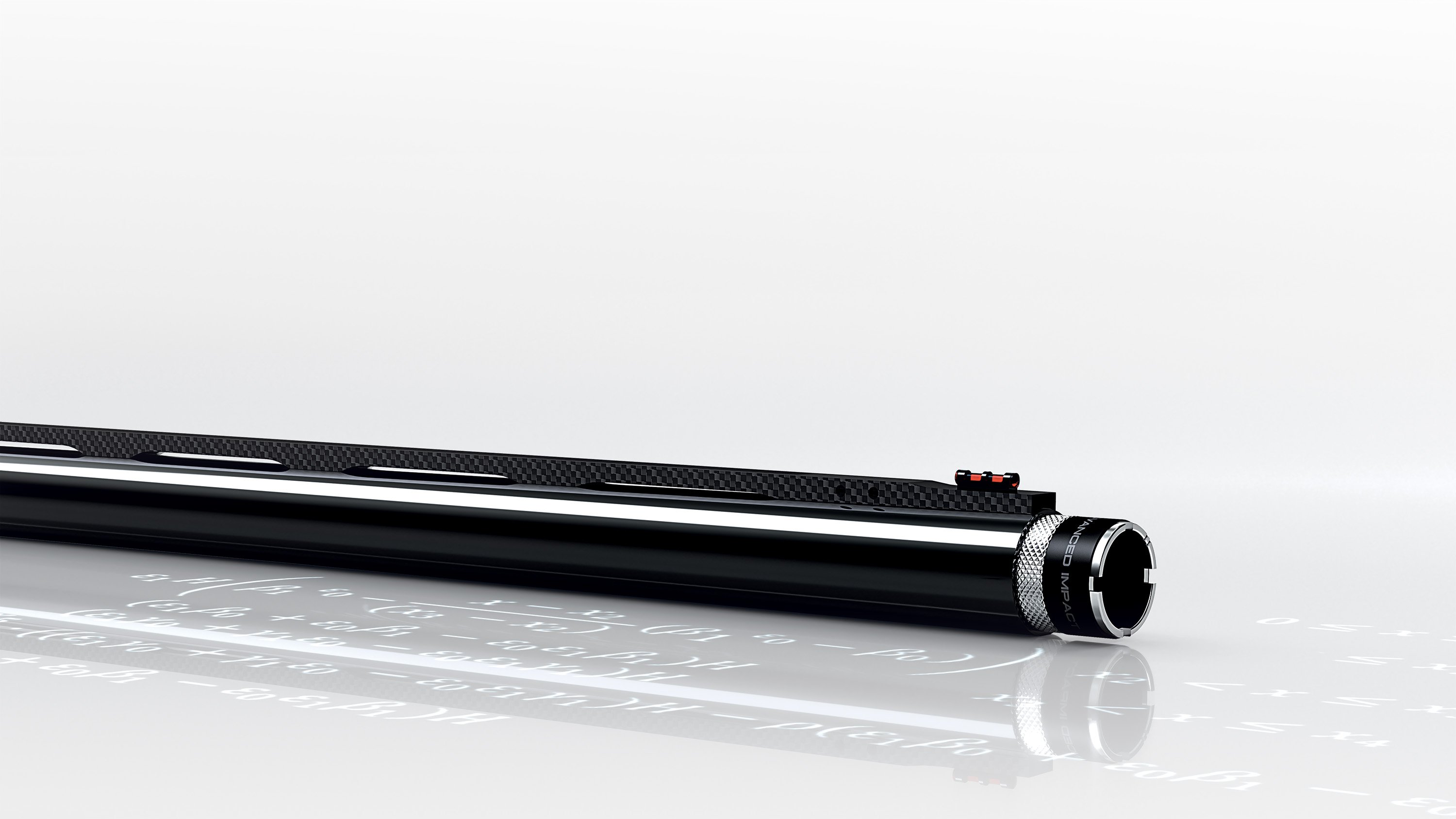

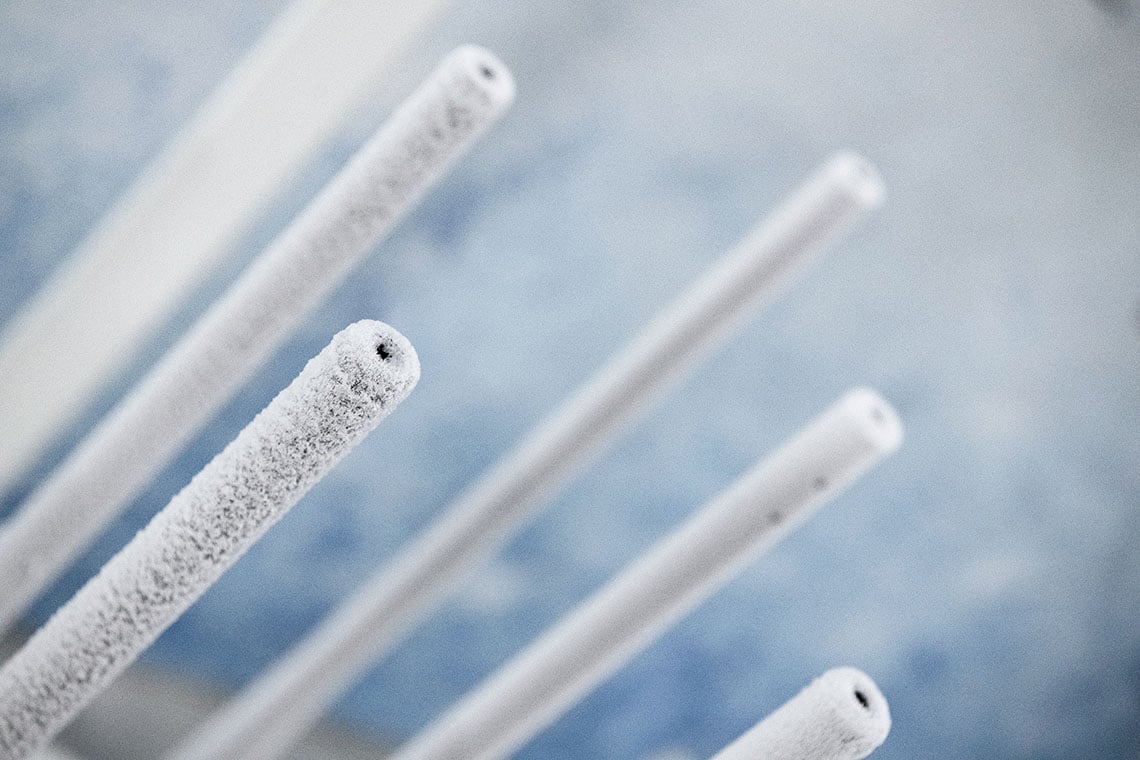

65/26 cm/" 70/28 cm/" 76/30 cm/" Advanced Impact barrel with ventilated carbon fibre flat rib; Interchangeable choke 5 INTERNAL 100 mm */**/***/****/CYL

STOCK AND FORE-END

Stock with Progressive Comfort System; Stock and forend grade 3 oil Walnut Wood

STOCK LENGTH TRIGGER MEASURED / DEVIATION

Standard 375 mm modifiable to 385 mm with long recoil pad or to 365 mm with dedicated stock. Compact 345 mm modifiable to 355 mm with long recoil pad

WEIGHT

3450 gr

PACKAGING

828 U A.I. BE.S.T. Steel is supplied in a polymer case that follows the style of the latest generation Benelli packages. The tartan inner lining gives an unmistakable touch of elegance. The internal structure is versatile and modular, the barrels-fore-end section and the recoil pad-receiver section are sized and equipped to accommodate 828 S A.I. in any configuration you want to customise.

TRIGGER ACTION

1.6 Kg (1st trigger); 1.6 Kg (2nd trigger) Detachable trigger group

The technical features and images on the web site are purely approximate, can be improved and / or changed at any time without notice.

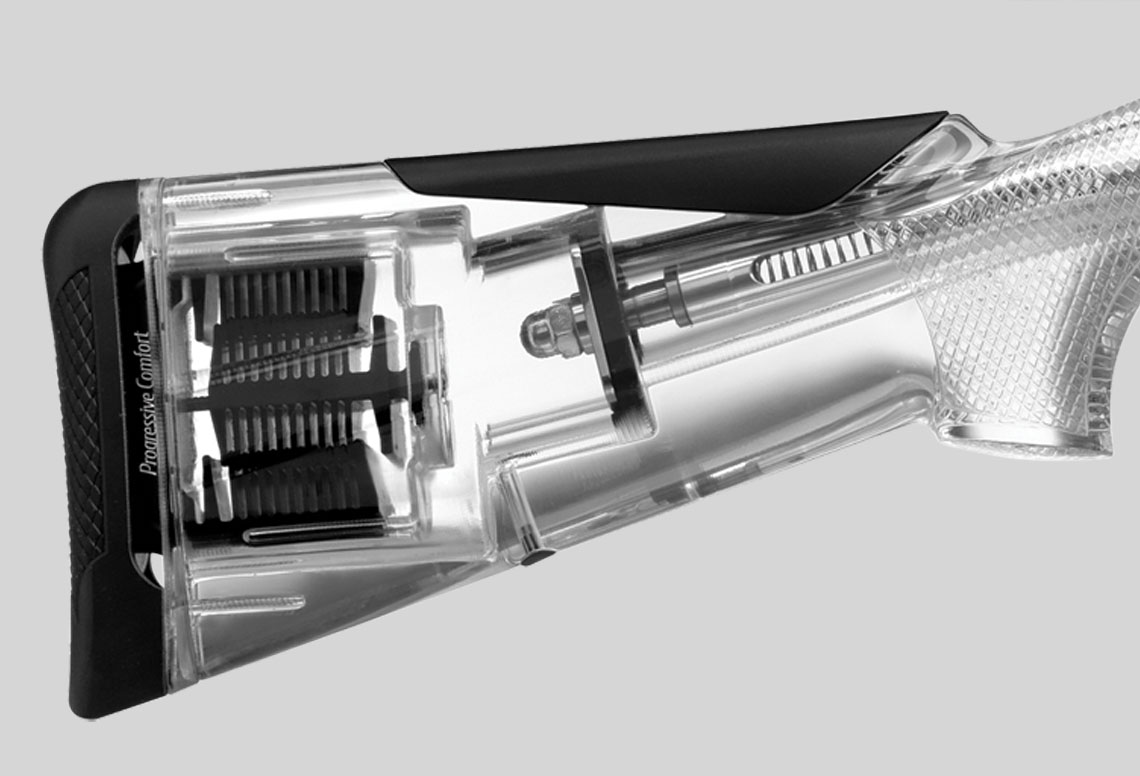

Progressive comfort

The innovative progressive recoil absorption system kicks in gradually according to cartridge and ammunition loading. This is the true essence of comfort, an invisible, yet highly sensitive system.

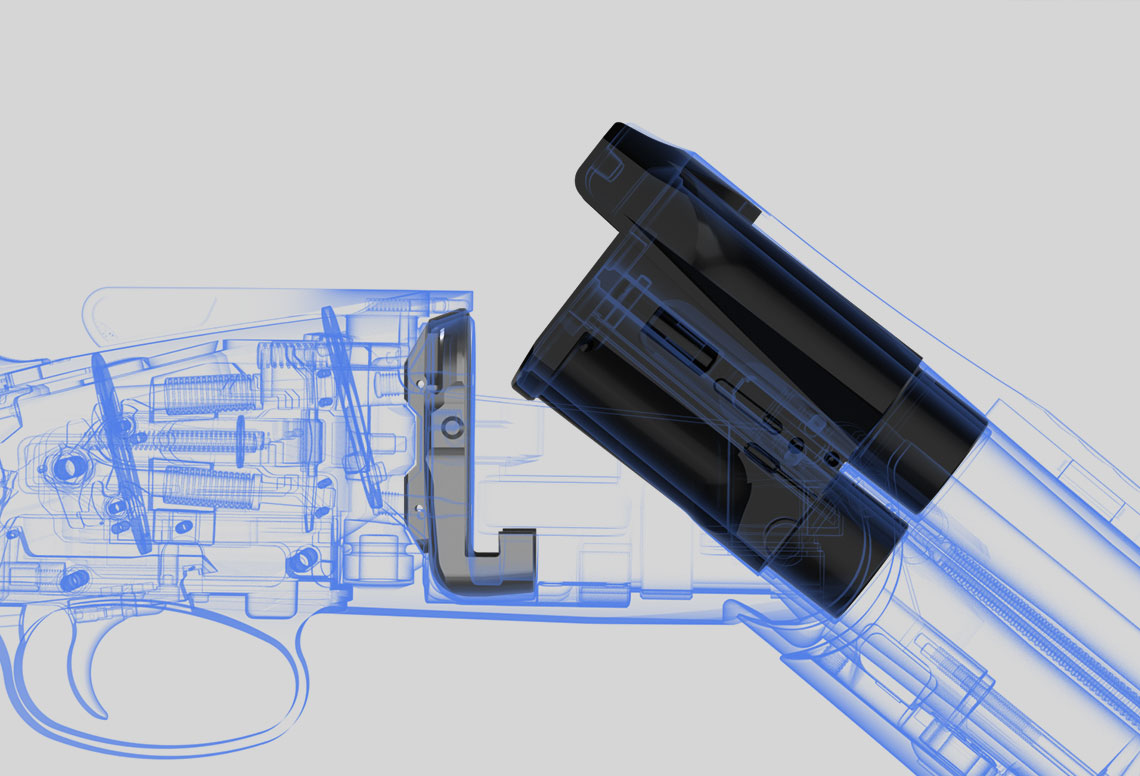

Perfect Fit

Perfect Fit overcomes the traditional barriers of drop and deviation providing easily customised solutions. Fast shouldering and instinctive aiming are ensured by the countless options to fine-tune drop and deviation (40 combinations: 20 rh-20 lh) to your specific needs. Optimum performance and tailored comfort are within your reach.

Lock Plate

The patented locking system consists of a plate that perfectly seals the single-piece unit. The firing pressure remains contained in the plate/single-piece assembly, reducing the stress applied to the rotating pins. The 828 U's steel locking system is durable and guarantees the elimination of any mechanical stress on the receiver.

Benelli Advanced Impact

Benelli Advanced Impact (Benelli A.I.) is not a simple brand-new barrel, it is a real patented system consisting of two inseparable elements that work together: barrel and choke. At the end of a long research and development work, what can be defined as the best internal profile to date has been identified to redesign the barrel-choke assembly and achieve performances never experienced before.

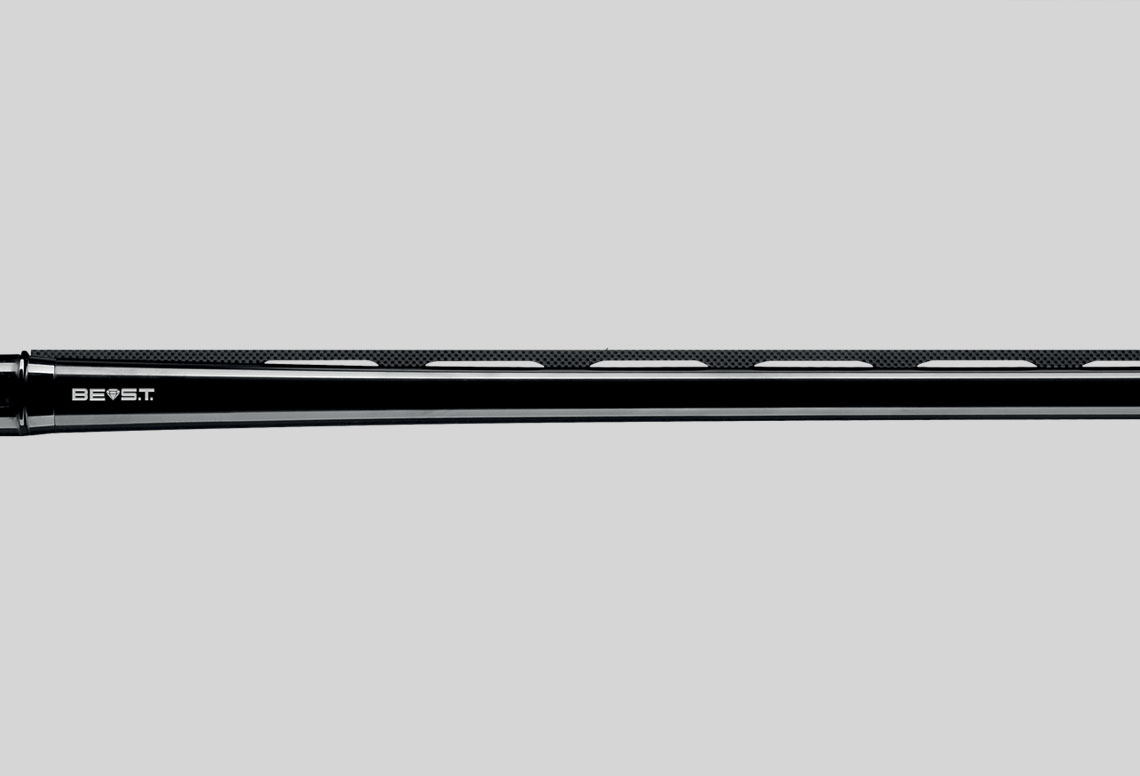

BE.S.T.

BE.S.T. is an exclusive Benelli technology to guarantee maximum resistance to corrosion, abrasion, wear and the elements. BE.S.T. surface treatment uses cutting-edge hybrid technology, covered by trade secret. The coating has characteristics similar to those of a diamond when it comes to hardness, resistance and precious finish. BE.S.T. is completely eco-friendly, since the process used involves no dangerous emissions for the environment.

Crio System

In cryogenic technology, the first element you need to consider is the barrel. The expansion caused by friction heat and pressure is limited, so that the barrel can vibrate and expand evenly on firing. The pattern provided by a cryogenic barrel is wider, more regular and more uniform, with pattern centres that will not shift as you fire shot after shot, to the benefit of shooting accuracy. Cryogenic treatment also has positive effects on the life of the barrel, which is more resistant to wear and less susceptible to attack by combustion residues. Benelli was the first company to apply Cryogenic Treatment to the barrel and choke of a light firearm on an industrial scale in order to enhance its ballistic performance.